Let's talk about lab water

Let's talk about lab water

Power-to-X, the process of converting electricity into various forms of energy or products, presents exciting opportunities for sustainable development. Converting surplus renewable electricity into valuable chemicals, generating green hydrogen, and reducing reliance on fossil fuels are just a few examples of the capabilities of Power-to-X technology. These innovative solutions could transform industries driving the transition towards a circular economy. In this blog I explore the potential of Power-to-X to mitigate greenhouse gas emissions and pave the way for a more sustainable future across various sectors.

Disclaimer: This image was generated by artificial intelligence and may not be an entirely accurate representation of the processes discussed.

Green hydrogen is what many scientists envision when considering electrolysis within the realms of sustainability - hydrogen and oxygen are the products of splitting water using renewably sourced electricity. Further, if the hazards of hydrogen production, distribution and storage can be solved, green hydrogen seems like the perfect replacement for fossil fuel; generating no greenhouse emissions when it is made, and solely producing water when combusted. While the current cost of green hydrogen production remains higher than that of conventional hydrogen production methods (grey hydrogen from natural gas via steam methane reforming), significant cost reductions are anticipated in the coming years. This is estimated to be up to a 50% decrease by 2030 according to a PwC analysis, driven by economies of scale, technological advancements and increased renewable energy capacity [1]. However, green hydrogen’s path to the mainstream is not clear, requiring:

Niche requirements for hydrogen are however suggested, namely long-duration energy storage and potentially in time as “an extraordinarily valuable offtaker for green electricity” [4].

Veolia and ELGA, as water technology experts, can ensure water quality and quantity, regardless of the source, via best-in-class technologies from reverse osmosis to continuous electrodeionization (CEDI). Depending on location, water scarcity is a deepening concern, and electrolyzer manufacturers can have limited freshwater resources. To ensure water access does not become a barrier to scale-up electrolysis, the ability to manage a variety of water sources, including treated wastewater and sludge, is invaluable.

Veolia experts can treat the water from a variety of sources for example: groundwater, surface water and seawater desalination. Additionally, to ensure maximum water recovery, water reuse is essential and zero liquid discharge (ZLD) ensures a reduction in wastewater disposal costs. For offshore installations or those near the sea, thermal desalination is an economically convenient solution. [2]

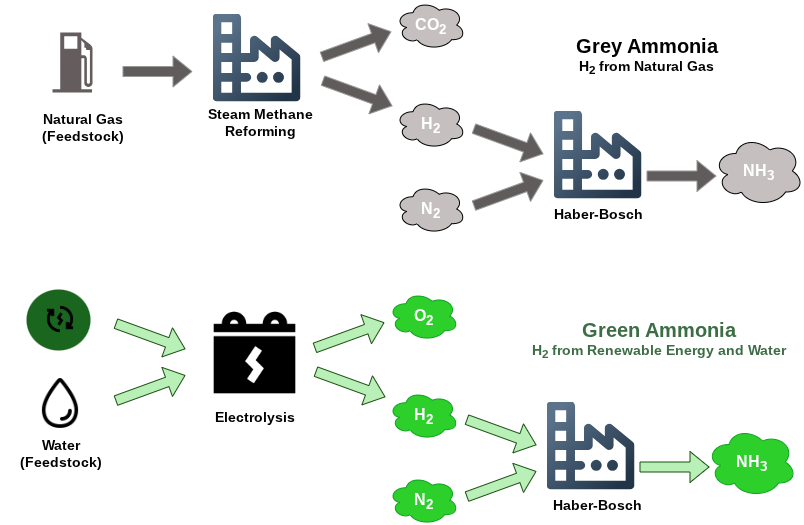

A solution to the distribution and storage of green hydrogen is instead its use as a feedstock for ammonia production, alongside the use of renewable electricity to power the reactors. The major use of ammonia globally is in fertiliser production, but it is also used as a major refrigerant, and contributor to explosives, textile and pharmaceutical production, with proposed future uses as an energy store or transport fuel [5]. Current ammonia production is responsible for ~ 1.8 % of global CO₂ emissions - the use of hydrogen from steam reformation of methane from natural gas innately couples the process with fossil fuel extraction [5].

Green ammonia production has its own obstacles to overcome of course: as with hydrogen, the price, availability and intermittency of green energy. This intermittency can in-turn cause issues with catalyst performance and lifetime, and the efficiency of the Haber Bosch process [5], which is the current industrial method for ammonia production. The more radical option for green ammonia production is the direct electrolysis of water with the reduction of nitrogen from air, eliminating issues with intermittency of green electricity, but this requires significant further development [6].

Where green energy production has been successfully established, there is often an excess of generation capacity, due to intermittent production and grid constraints [7]. This energy cannot be utilised, and so its production is curtailed, which creates a loss for energy companies. However, this loss is currently protected by government subsidies which ultimately costs the taxpayer [8].

Instead, this green electricity can be efficiently used in the synthesis of chemicals. Promisingly, this can include CO₂ as a feedstock, providing dual benefits of removing CO₂ from the atmosphere or flue gases, limiting the greenhouse effect, and reducing the reliance on virgin carbon for the chemical industry. This has been evidenced as Power-to-X-to-Y in the EU project “Cost-effective CO₂ conversion into chemicals via combination of capture, ELectrochemical and BIochemical CONversion technologies – CELBICON” [9].

An example is the co-electrolysis of carbon dioxide and water for the production of ethylene, offering a promising option for carbon capture, utilisation and storage (CCUS). New innovations including the use of membrane electrode assembly electrolysers instead of flow cell setups greatly increase the energy conversion efficiency. Further, the use of solid-state polymer electrolytes and ultra-pure water (UPW) instead of liquid electrolytes prevents issues like electrolyte leakage and cathode failure due to salt precipitation. Wenzheng Li et al. propose a bifunctional polymer electrolyte (ionomer) that can run on pure water in alkaline conditions to address these challenges [10].

Further examples include commercial ventures such as Zero - the passion project of former F1 Executive-Director, Paddy Lowe “fuelled by a childhood dream of sustained, clean burning power”. Their technology combines Direct Air Capture (DAC) of CO₂, electrolysis and their proprietary Fischer-Tropsch technology initially for the synthesis of fuels, but with ambitions to expand to all crude oil based products [11].

Similarly, Avioxx, among others, plan to reduce the environmental impact of flying through the production of economical, sustainable aviation fuel (SAF) from household waste. Their process combines gasification, generation of electricity through solid oxide fuel cells, electrolysis, and the Fischer-Tropsch reaction [12]. The importance of SAF is evidenced by the introduction of a UK government bill and mandate, subject to Parliamentary approval, to support SAF production, and make its contribution to UK jet fuel demand obligatory [13].

An alternative to DAC as utilised above could be the capture of CO₂ from seawater. CO₂ only represents < 0.05 % by volume in air, whereas the Earth’s oceans have an effective CO₂ concentration 0.095 kg m−3, more than 120 times higher [14]. Methods include the electrolysis of seawater to form acid and base streams:

Equatic's electrolysis system also produces carbon-negative hydrogen, which can power 40% of their CO₂ removal process or serve hard-to-abate industries [16].

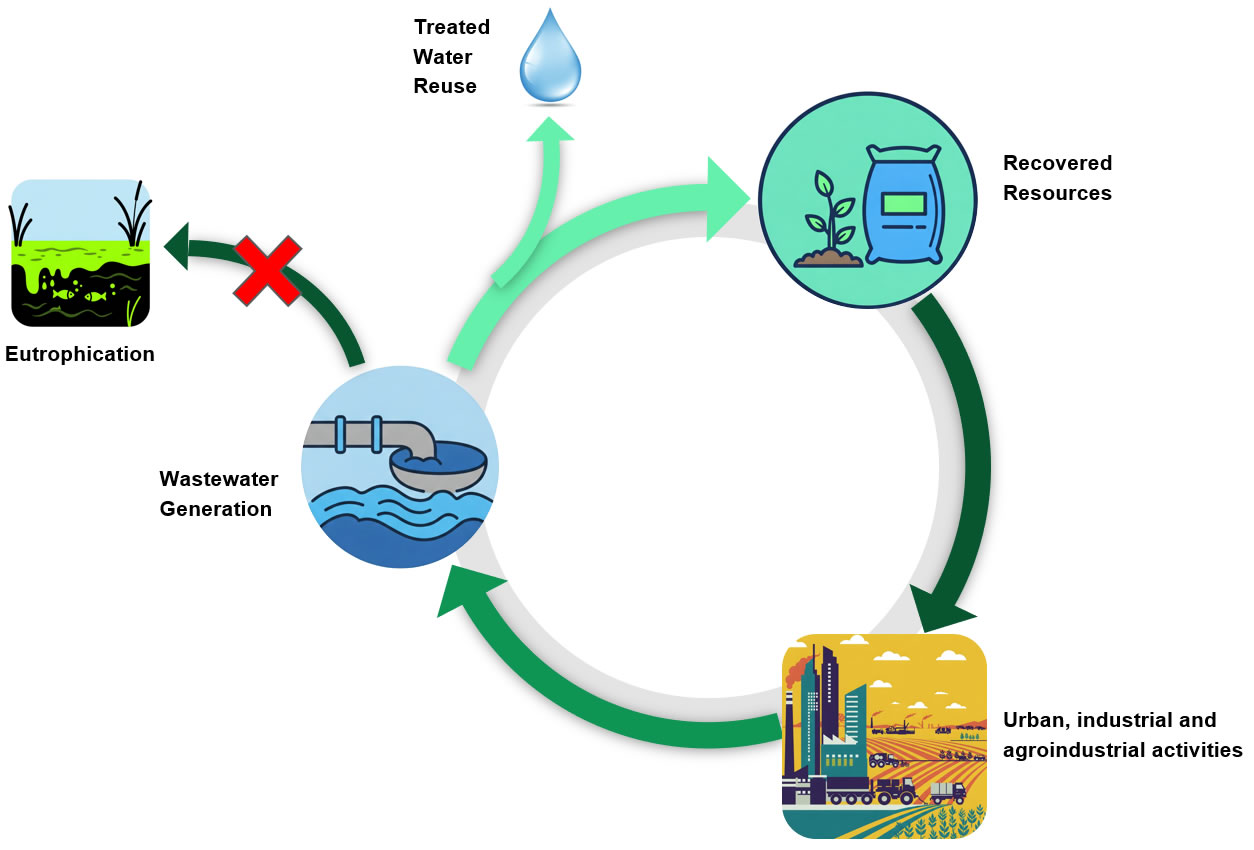

Electrochemical solutions can also be found for other environmental problems aside from Power-to-X solutions that require pure water. Excessive application of fertilisers, particularly non-organic nitrogen compounds, to agricultural land, can cause overload of nitrates and ammonium in wastewater streams. This can be severely harmful to aquatic ecosystems, often causing eutrophication (significant algal blooms that deplete oxygen levels and sunlight in surface waters). Dean Miller et al. have designed a novel “electrocatalyst-in-a-box” for the conversion of wastewater nitrate into a purified ammonia product (ammonium sulfate) that was successful in the treatment of real municipal wastewater. Experiments with synthetic wastewater elucidated the inhibitive effect of other ions in the water, eg. Mg2+ which was limited by the use of a homogeneous catalyst Co(DIM) and Donnan membrane dialysis allowing cathode protection and catalyst reuse [17].

Power-to-X technologies represent a crucial step towards a sustainable future, offering innovative solutions to some of our most pressing environmental challenges. These processes demonstrate the versatility and potential of converting renewable electricity into valuable products and services. As research progresses and technologies mature, we can expect Power-to-X to play an increasingly significant role in eliminating fossil fuel use and mitigating environmental CO₂, overall creating a more circular economy. The continued development and implementation of these technologies will be essential in our global efforts to combat climate change and build a more sustainable world.

ELGA Labwater is established in the supply of high purity water for application in scientific practices, with ELGA purifiers reliably and consistently providing high purity water that can be used with confidence to support the development of new green technologies. The ELGA PURENERGY 30 water purification system is designed to directly feed PEM Electrolyser Systems with make up rates of up to 30 L/hour, enabling the production of up to 30 Nm3/h of hydrogen. The environmental focus of the Veolia group makes ELGA the sustainable choice for high purity water in the laboratory.

Disclaimer: The images used in this blog were generated with the support of artificial intelligence and may not be entirely accurate representations of the processes discussed.

[1] PWC The green hydrogen economy: Predicting the decarbonisation agenda of tomorrow https://www.pwc.com/gx/en/industries/energy-utilities-resources/future-energy/green-hydrogen-cost.html

[2] VWT Hydrogen Production https://www.veoliawatertechnologies.com/en/core-markets/hydrogen-production

[3] Let’s be realistic about green hydrogen, Robin Gaster, March 2024 https://www.utilitydive.com/news/green-hydrogen-production-scale-economies-clean-energy/709262/

[4] A Realist Approach to Hydrogen, Robin Gaster, January 2024 https://itif.org/publications/2024/01/16/a-realist-approach-to-hydrogen/

[5] “Ammonia: zero-carbon fertiliser, fuel and energy store” Policy Briefing, The Royal Society Issued: February 2020 DES5711 ISBN: 978-1-78252-448-9

[6] Jin H, Kim SS, Venkateshalu S, Lee J, Lee K, Jin K. Electrochemical Nitrogen Fixation for Green Ammonia: Recent Progress and Challenges. Adv Sci (Weinh). 2023 Aug;10(23):e2300951. doi: 10.1002/advs.202300951

[7] National Grid Electricity System Operator Limited, Future Energy Scenarios: ESO Pathways to Net Zero, 2024 https://www.neso.energy/publications/future-energy-scenarios-fes

[8] Research Briefing - Contracts for Difference, Nicole Watson and Paul Bolton, October 2024

https://researchbriefings.files.parliament.uk/documents/CBP-9871/CBP-9871.pdf

[9]CELBICON – Cost-effective carbon dioxide conversion into chemicals, Fraunhofer IGB https://www.igb.fraunhofer.de/en/reference-projects/celbicon.html

[11] https://www.zero.co/technology

[12] https://www.avioxx.co.uk/process.html

[13] Written statement to Parliament: Sustainable aviation fuel initiatives, Department for Transport and The Rt Hon Louise Haigh MP 22 July 2024 https://www.gov.uk/government/speeches/sustainable-aviation-fuel-initiatives

[15] Startups aim to curb climate change by pulling carbon dioxide from the ocean—not the air, Robert F. Service, March 2024 https://www.science.org/content/article/startups-aim-curb-climate-change-pulling-carbon-dioxide-ocean-not-air

[16] https://www.equatic.tech/the-equatic-process

Interested in sustainable solutions for your business? Contact our team to explore tailored strategies

Contact Us