Predictable Running Costs At Higher Volumes

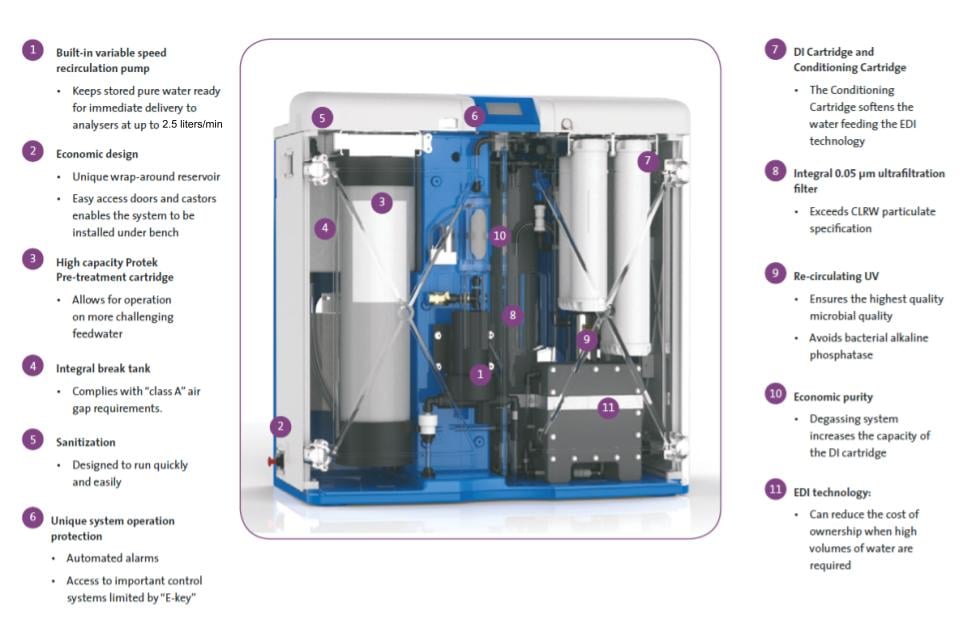

The MEDICA Pro range is specifically designed to meet the water quality needs of high performance, high volume single or multiple Clinical Diagnostic Analyzers. The MEDICA Pro EDI incorporates EDI ‘Pulse Technology’ using Electrodeionization (EDI). The system delivers 2.5 l/min of CLSI CLRW water with up to 60 or 120 l/hr productivity to meet your analyzer requirements. The single system design incorporates all the water purification components plus a 50-liter storage reservoir to ensure a very quick and cost-effective installation.

Tech Specs

| PRODUCT SPECIFICATIONS | MEDICA PRO EDI 60 | MEDICA PRO EDI 120 |

|---|---|---|

| Dispense flowrate | 60 l/hr | 120 l/hr |

| Inorganics (resistivity at 25°C) | >10 MΩ.cm | >10 MΩ.cm |

| Organics (TOC) | <30 ppb | <30 ppb |

| Bacteria | <1 CFU/ml * | <1 CFU/ml * |

| Particles | 0.05 μm filter | 0.05 μm filter |

| Silica | <0.05 mg/l | <0.05 mg/l |

| Delivery flow rate | Up to 2.5 l/min @ 14psi (1bar) | Up to 2.5 l/min @ 14psi (1bar) |

| PRODUCT SPECIFICATIONS | MEDICA PRO EDI 60 | MEDICA PRO EDI 120 |

|---|---|---|

| Dispense flowrate | 60 l/hr | 120 l/hr |

| Inorganics (resistivity at 25°C) | >10 MΩ.cm | >10 MΩ.cm |

| Organics (TOC) | <30 ppb | <30 ppb |

| Bacteria | <1 CFU/ml * | <1 CFU/ml * |

| Particles | 0.05 μm filter | 0.05 μm filter |

| Silica | <0.05 mg/l | <0.05 mg/l |

| Delivery flow rate | Up to 2.5 l/min @ 14psi (1bar) | Up to 2.5 l/min @ 14psi (1bar) |

*Subject to correct operating and maintenance procedures.

Installation of a MEDICA Pro EDI unit requires a starter kit, please order either LC237 or LC238.

Consumables

FAQs

- What is the MEDICA product range?

The MEDICA product range is specifically targeted at the Clinical diagnostics market. The MEDICA will either directly feed (analysers which require a direct feed) or fill via a dispense gun the analyser with water that meets the recommendations of the Clinical Laboratory Standards Institute (CLSI).

- How often do I need to change my consumables?

Consumables life depends entirely on the quality and volume of water being fed into the MEDICA product. Higher volumes and lower quality water will increase consumables usage.

- What feedwater is required?

Normally potable water is sufficient as feedwater. However, the quality of potable water can vary between countries and regions. Feed water specifications can be found in the operators manual and the data sheet of the product. It is important that if the feedwater specification is exceeded suitable pre-treatment be installed to bring the feedwater within specifications.

- What is the MEDICA Pro EDI?

The MEDICA Pro EDI is designed to reduce the running costs associated with purified water purification. This is because the EDI stack removes significant ionic content from the water before the water passes through downstream consumables, lowering the number of consumables which need to be changed. The MEDICA Pro EDI also contains a degasser to remove CO2.

- If it is cheaper to run should I always purchase the MEDICA EDI?

Low quality feedwater with very high ionic content can cause saturation of the EDI stack nullifying its benefits. It is therefore important to ensure that the feedwater is within the product specifications.

- Why remove CO2 from the water?

CO2 acts as a weakly charged ion which affects the purity of the water. It is removed by the Deionisation packs down stream which causes them to expire more quickly. Removing CO2 helps lengthen the life of consumables lowering your costs of ownership.

- How much CO2 should be in the water?

The CO2 levels are set out in the feedwater specifications.

WHITEPAPER